Air flow -

All heating and cooling equipment needs a certain amount of air flow. This is measured in CFM (cubic feet per minute). With too little or too much airflow furnaces and air conditioners cannot work as they should. So how much is the "right" amount.

For furnaces we multiply the heating capacity, measured in btu (British thermal units) by a multiplier. This will give us a minimum airflow number. Some systems require more airflow than this.

For 90% high efficiency furnaces (pvc vented) this is 0.015

For 80% standard efficiency furnaces (metal vented with an inducer motor and no pilot) this is 0.013

For 60-70% efficiency furnaces (metal vented with natural draft and/or a pilot) this is 0.010

For example: an 80k btu (80,000) high efficiency furnace * 0.015 = 1200 cfm.

For example: an 80k btu(80,000) standard efficiency furnace * 0.013 = 1040cfm

Air conditioners require 350-400 cfm per ton of airflow. A ton is 12,000 btu. We typically budget for 400 cfm of air giving us room to dial airflow down for better dehumidification.

For example: A 3 ton system (36,000 btu) * 400 cfm = 1200 cfm airflow required.

For example: A 5 ton system (60,000 btu) * 400 cfm = 2000 cfm airflow required.

http://contractingbusiness.com/archive/finding-system-required-airflow

What influences airflow? The ductwork, the air filter, the indoor coil, and the registers. The more restrictive these are, the more likely your airflow is below what is required and is causing excess stress and increased operating cost.

Here's an easy one to check. Do you have a 1" filter? If yes, see below

Here are the maximum airflow for these are filters:

14x25x1 = 600 cfm (1.5 tons cooling)

16x25x1 = 800 cfm (2 tons cooling)

20x25x1 = 1000 cfm (2.5 tons cooling)

https://www.hartandcooley.com/assets/files/1p5/hcb_851531_engineeringdata_13ed_june2017_web.pdf#page=7

So why would we need a larger filter installed like the picture below?

Lets share a little more info.

Standard furnaces sizes are 40k, 60k, 80k, 100k, and 120k

Standard ac sizes are 1.5, 2, 2.5, 3, 3.5, 4, and 5 ton. Remember each ton is 12k btu.

If we look at the middle of the road furnace and ac size (80k and 3 ton) both require a filter larger than 20x25x1 and I would say is the largest filter we see in the 1" orientation. This is number one reason why we recommend a media air filter on every job. Their surface area is much larger, meaning they allow much more air to pass through the filter, they remove a greater amount of particulate from the air, and they protect our equipment. There's far more to discuss here but this is the black and white of why many filters we encounter are too small, negatively affecting your furnace.

All heating and cooling equipment needs a certain amount of air flow. This is measured in CFM (cubic feet per minute). With too little or too much airflow furnaces and air conditioners cannot work as they should. So how much is the "right" amount.

For furnaces we multiply the heating capacity, measured in btu (British thermal units) by a multiplier. This will give us a minimum airflow number. Some systems require more airflow than this.

For 90% high efficiency furnaces (pvc vented) this is 0.015

For 80% standard efficiency furnaces (metal vented with an inducer motor and no pilot) this is 0.013

For 60-70% efficiency furnaces (metal vented with natural draft and/or a pilot) this is 0.010

For example: an 80k btu (80,000) high efficiency furnace * 0.015 = 1200 cfm.

For example: an 80k btu(80,000) standard efficiency furnace * 0.013 = 1040cfm

Air conditioners require 350-400 cfm per ton of airflow. A ton is 12,000 btu. We typically budget for 400 cfm of air giving us room to dial airflow down for better dehumidification.

For example: A 3 ton system (36,000 btu) * 400 cfm = 1200 cfm airflow required.

For example: A 5 ton system (60,000 btu) * 400 cfm = 2000 cfm airflow required.

http://contractingbusiness.com/archive/finding-system-required-airflow

What influences airflow? The ductwork, the air filter, the indoor coil, and the registers. The more restrictive these are, the more likely your airflow is below what is required and is causing excess stress and increased operating cost.

Here's an easy one to check. Do you have a 1" filter? If yes, see below

Here are the maximum airflow for these are filters:

14x25x1 = 600 cfm (1.5 tons cooling)

16x25x1 = 800 cfm (2 tons cooling)

20x25x1 = 1000 cfm (2.5 tons cooling)

https://www.hartandcooley.com/assets/files/1p5/hcb_851531_engineeringdata_13ed_june2017_web.pdf#page=7

So why would we need a larger filter installed like the picture below?

Lets share a little more info.

Standard furnaces sizes are 40k, 60k, 80k, 100k, and 120k

Standard ac sizes are 1.5, 2, 2.5, 3, 3.5, 4, and 5 ton. Remember each ton is 12k btu.

If we look at the middle of the road furnace and ac size (80k and 3 ton) both require a filter larger than 20x25x1 and I would say is the largest filter we see in the 1" orientation. This is number one reason why we recommend a media air filter on every job. Their surface area is much larger, meaning they allow much more air to pass through the filter, they remove a greater amount of particulate from the air, and they protect our equipment. There's far more to discuss here but this is the black and white of why many filters we encounter are too small, negatively affecting your furnace.

Aprilaire 1510 media air filter. Cabinet dimensions are 31" wide x 28" deep x 6.75" high

https://www.aprilaire.com/whole-house-products/air-purifiers/model-1510

Custom installation for a horizonal furnace

Air Filter direction

All filters airflow arrow point toward the furnace. For conventional filters I recommend pleated filters which are changed every 60-90 days. The less expensive filter are typically referred to as fiberglass filters and are changed every 30 days. Here's what the epa recommends...."Change your air filter regularly. Check your filter every month, especially during heavy use months (winter and summer). If the filter looks dirty after a month, change it. At a minimum, change the filter every 3 months. A dirty filter will slow down air flow and make the system work harder to keep you warm or cool — wasting energy. A clean filter will also prevent dust and dirt from building up in the system — leading to expensive maintenance and/or early system failure."

With a conventional filter I recommend the pleated 3 packs commonly available at Home Depot and Lowes for $8. Less filtration and too much dirt bypasses the filter and better filtration (based on the 1" surface area) and the filter causes too much restriction.

http://www.energystar.gov/index.cfm?c=heat_cool.pr_hvac

With a conventional filter I recommend the pleated 3 packs commonly available at Home Depot and Lowes for $8. Less filtration and too much dirt bypasses the filter and better filtration (based on the 1" surface area) and the filter causes too much restriction.

http://www.energystar.gov/index.cfm?c=heat_cool.pr_hvac

High Efficiency Furnace sidewall termination kit

Whenever possible we will install a sidewall termination kit to present our customers with a finished look for their furnace flue and combustion air.

|

Front view of the termination kit. There are 2 pipes that terminate to this kit. The flue exhausts spent gases out of the hole you can see. The second pipe pulls fresh air from against the house, which is naturally separated from the flue gases.

Sideview of the termination kit

|

This is the alternative to a sidewall termination kit and required when the piping is too low to the ground or the piping is not properly spaced (previously installed)

We have core bits to cleanly install the termination kit on a brick home

|

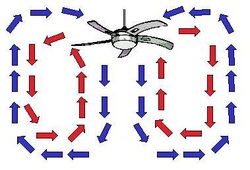

Ceiling Fan Direction

Turn Off When not in the Room -- Ceiling fans cool people, not rooms. If the room is unoccupied, turn off the ceiling fan to save energy.

Using the Ceiling Fan Year Round -- In the summer, use the ceiling fan in the counterclockwise direction. While standing directly under the ceiling fan you should feel a cool breeze. The airflow produced creates a wind-chill effect, making you "feel" cooler. In the winter, reverse the motor and operate the ceiling fan at low speed in the clockwise direction. This produces a gentle updraft, which forces warm air near the ceiling down into the occupied space. Remember to adjust your thermostat when using your ceiling fan — additional energy and dollar savings could be realized with this simple step!

http://www.energystar.gov/index.cfm?c=ceiling_fans.pr_ceiling_fans_usage

Using the Ceiling Fan Year Round -- In the summer, use the ceiling fan in the counterclockwise direction. While standing directly under the ceiling fan you should feel a cool breeze. The airflow produced creates a wind-chill effect, making you "feel" cooler. In the winter, reverse the motor and operate the ceiling fan at low speed in the clockwise direction. This produces a gentle updraft, which forces warm air near the ceiling down into the occupied space. Remember to adjust your thermostat when using your ceiling fan — additional energy and dollar savings could be realized with this simple step!

http://www.energystar.gov/index.cfm?c=ceiling_fans.pr_ceiling_fans_usage